Yet what we see are fluorescent bulbs everywhere.

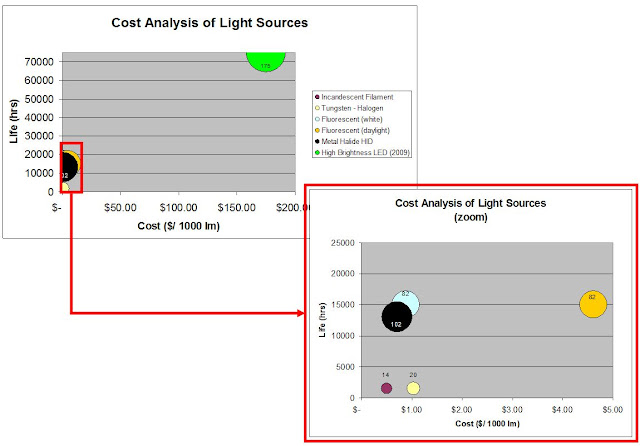

One way to compare these light sources is by bulb life vs cost per lumen output with efficacy taken into account. That looks like this: "Good" is high and to the left with a larger bubble.

One conclusion that immediately stands out is how expensive LED lights are relative to the alternatives. They may be 2x as efficient and last 5x as long, but they are ~38x - 175x the price. That makes adoption of LEDs very difficult for most applications that don't have some other needs specifically met by LEDs.

Some of those special needs:

- LEED certification

- LED lighting is more efficient so it can be used towards energy efficiency credits (EAc1). If 25% of a commercial building's electricity usage goes towards lighting and you can cut that by 50%, that's a 12.5% reduction in electricity cost.

- LED lighting is more easily controlled (dimmable) to allow for controllability of systems - lighting (EQ6.1).

- Flicker

- For some tasks and working conditions, 60Hz cycling from fluorescents can cause eye strain, especially if it is used with other visual equipment that runs off 60Hz AC. LED lighting has a 120Hz cycling which means it is much more difficult to detect flicker and it is less likely to beat with other equipment running at 60Hz.

- Dimming

- Commercial use fluorescent bulbs (T8, T10 and T12) are not easily dimmable due to the construction of the ballast that keeps them lit. LEDs are dimmable using standard dimming equipment. This is important for applications where light level control is desired.

- Directionality

- LEDs are point sources that can be configured more easily to provide a variety of lighting patterns (focused to diffuse) while fluorescent bulbs are generally quite long making it more difficult to use as task lighting or for other special lighting purposes.

- Toxic waste disposal concerns

- Fluorescent bulbs contain mercury which is a hazardous substance. LEDs do not contain mercury, though they are still eWaste and need special handling for disposal.

- Low temperature operation

- LED lighting performs better at lower temperatures. In fact, life time if greatly reduced if they operate at too high temperatures (hence all the heat sinks on the LED bulbs). This makes LED lighting a natural fit for lighting refrigerated displays.

- Green image

- The current perception of LED lighting is that it is the next big thing in energy efficiency and is, therefore, green. Using this perception to advertise your greenness is good marketing.

So as the cost of LEDs drop (cost comes in line with alternatives), energy costs rise (efficacy difference becomes more important) and green building codes become more prevalent (raising the minimum energy efficiency requirements for new buildings), the ROI of LED lighting will rise vs fluorescents until LED lighting makes economic sense.

It's just not quite there today.

No comments:

Post a Comment