It is an interesting observation, the same one made by William McDonough & Michael Braungart in Cradle to Cradle, that Azby makes towards the end of his essay: that easy access to large amounts of cheap power brought this need to use leverage to an end. With the loss of that need, so too was (nearly) lost the knowledge of the leverage itself.

"During the Edo period, from the early 17th to the mid 19th centuries, Japan faced environmental problems similar to ours: large population, fuel scarcity, limited arable land, deforestation, a damaged watershed. Through well-thought-out policies that reinforced existing cultural values, and through technical and economic innovation, the nation brought itself back from the brink, and did it in beautiful ways.

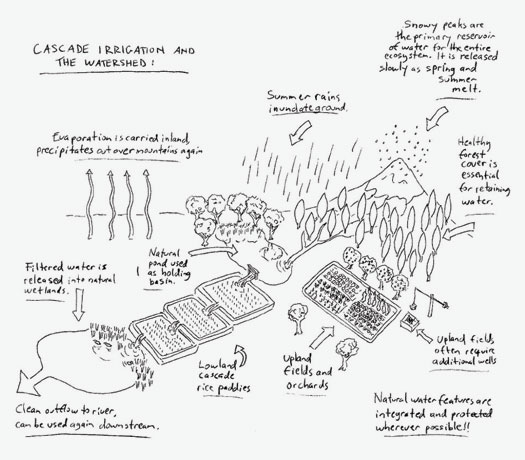

One of the most important lessons is that the primary design response to material and energy shortages of the era was to seek multiform solutions, designs that solved many problems at once. ... the same attitude led to the development of rice paddy irrigation systems, which were almost entirely gravity-fed, acted as cascading filters for the water supply, and could function as solar-heated warm-water tanks for processing hemp and other plant-based textile fibers. The system allowed the paddies themselves to function as wetland habitat for many species in addition to growing food.

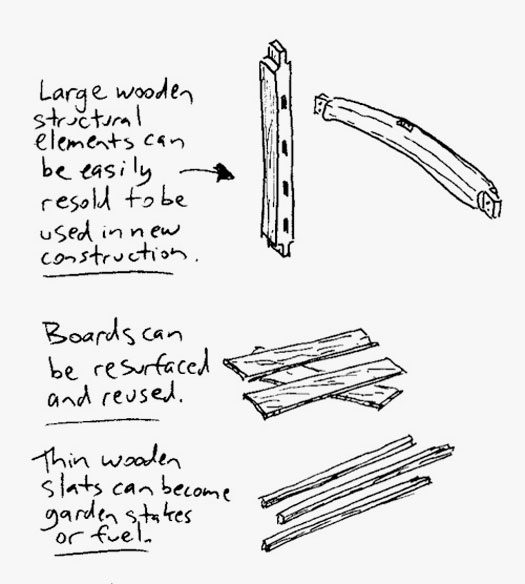

The design of the ubiquitous dismantleable Japanese jointed wooden building frame facilitated reusing the posts and beams elsewhere, helping to reduce the stress on forests for lumber supplies.

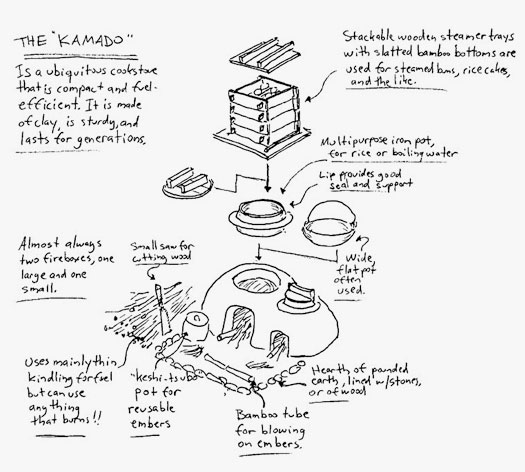

The constantly refined design of earthen cookstoves minimized fuel use and helped keep fuel consumption well within the available supply, further minimizing the stress on forests.

Forest management was recognized early on as essential for preserving the health of waterways that were vital for transportation and as a food source

Metal, mainly iron, whose production depended upon a high expenditure of energy in the form of large quantities of charcoal, was an extremely valuable commodity.... The near total absence of metal nails in architectural structures, depending instead on mortises, tenons, pegs and wedges, and the fact that nails were carefully salvaged and reused whenever possible, attests as much to the desire to minimize energy consumption in the form of embodied energy as it does anything else.

Can this be done without consuming fuel (like weaving)? Can it be made from a rapidly renewed material (bamboo for baskets, or reeds for thatch)? Can it take advantage of recycled material (a broken iron pot becomes a blade)? Is it scalable and able to be customized to suit specific regions, households or individuals (like kimono)? What is the desired degree of durability — is it better to make it last for generations (like cabinetry) or remade every year (like straw boots)? Is there a way to use the material at end-of-life (use the straw as fuel, convert worn cotton fabric to pouches)?

...by and large the intricately interconnected sustainable material production system broke down with the advent of the industrial revolution in Japan in the late 19th century. The widespread introduction of fossil fuels, coal primarily, broke the bond between people and the forests that had supported them..."

No comments:

Post a Comment